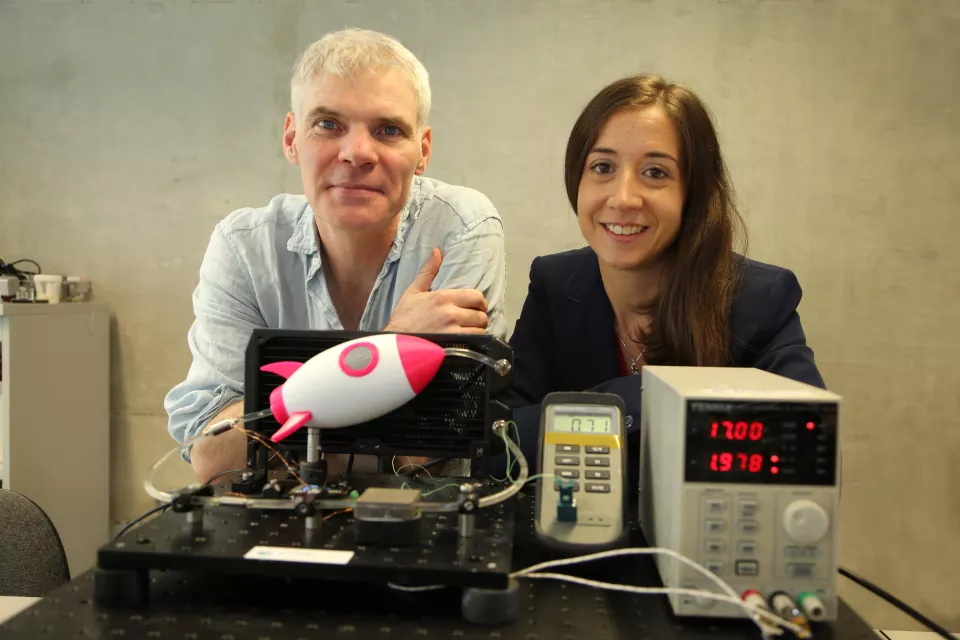

Dr Eric Dalton is a Research Fellow in the Stokes Laboratory in the Faculty of Science and Engineering at the University of Limerick. Together with his colleague Dr Valeria Nico, they have developed a microfluidic pump that can withstand the intolerable pressures that exist in space.

The pump was originally developed for cooling earth-based electronic applications ranging from medical devices to bio 3D-printing via funding from Enterprise Ireland. However, the Stokes team saw an opportunity to diversify its use, applying to the European Space Agency (ESA) in April 2020 through the Open Space Innovation Platform (OSIP) and securing funding in June 2021. The funding was to develop an ultra-reliable, high performance two-phase cooling pump capable of working under extreme pressures to cool small and large satellites, Dr Dalton explains:

“Space, to put it mildly, is a pretty nasty environment to operate in. There are a massive amount of constraints as you can imagine like weight, mass, energy; all of these factors have to be considered. One of the key aspects of operating small and large satellites is their electronic cooling. At the time we approached the ESA there were no small-scale pumps on the market that could match the specifications they were looking for, namely withstanding high working pressures (up to 60 atmospheres) and meeting stringent requirements for reliability.”

Traditional approaches to micropump technology have relied on a piezoelectric or a diaphragm type of system to circulate the coolant around the pump. However, the Stokes team took a different approach with their cooling system:

“We looked at traditional micropumping methods and how the driver system in these cooling loops is piezoelectric and is touching the fluid in the pump in order to circulate it. These methods are not particularly reliable and can’t operate at the pressures required for space travel. The solution to this was to use an electromagnetic system, meaning there is a little magnet inside that moves back and forth to circulate the coolant.”

The ESA was looking for a two-phase cooling system for their satellites using ammonia as a coolant because it is an excellent fluid for energy transfer. Testing of the system at the Stokes laboratory was done using an inert gas or one that was more stable due to the nature of ammonia and the requirements of a two-phase system:

“Under the right pressure conditions, the gas you are using will liquefy. The liquid is then pumped around the system until it hits the heat source, your CPU or whatever you want it to cool. The liquid boils and that's why it's called a two-phase cooling system. When it boils it becomes a gas-liquid mixture and this mixture is then transferred to a secondary heat exchanger. This is how you remove your heat from the system and then the gas recondenses to your liquid again and the cycle continues.”

The weight, size, and cost of production of the Stokes pumps also make them attractive for space travel:

“Our pumps are 10 grams in weight, 7 millimetres in diameter and about 20 millimetres long whereas pumps on existing satellites would be kilograms in weight. In space everything is an energy balance; power, weight, temperature, even the direction you are travelling in, for example, travelling towards the sun or away from it. The combination of these factors and that the pumps are cheap to produce makes them an attractive option. You could put 10 of our pumps on a satellite and if a pump were to fail, there would be plenty of backup capacity.”

The micropump technology developed by Dr Dalton and Dr Nico can be utilised in other industries and across other applications:

“Currently server cooling uses air and this is horribly inefficient. What big tech companies are looking at now is fluidic cooling using CO2; everything that makes our pumping system good for satellites is the very same for Earth-based applications except with a different gas.”

The research group in the Stokes laboratory works across disciplines depending on the project at hand and this is something that attracted Dr Dalton to becoming a Research Fellow:

“I was always interested in science, and understanding how something works in relation to the physical world around it. In our research group, we work on a variety of topics. Right now I’m working on a really interesting project concerning biology and optics, so our work changes with the demands of each project which is something I love.”

The team is currently in discussions with industry that could see their microfluidic pump go into orbit in the near future:

“We have a lot of faith in what we developed. I think it demonstrates that our team and University of Limerick can develop products from the ground up and that we have the expertise and the vision to make it happen. This is something that makes me immensely proud.”