Research Focus

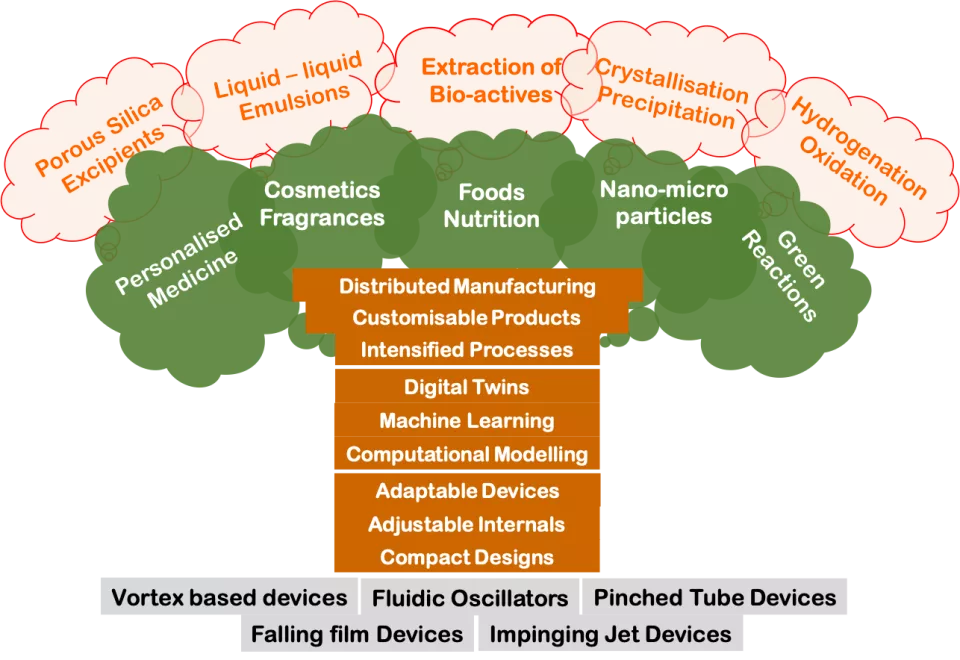

Resource conservation, recycle and reuse: via process intensification and reactor engineering

- Chemicals & materials: develop and apply novel process intensification strategies & devices to improve performance (selectivity, spatial foot print, environmental foot print, safety, etc)

- Energy: intensify waste biomass to energy & value added chemicals processes

- Water: develop novel distributed water treatment, recycle and reuse technologies

Tailoring functional products & materials: via new fluidic devices, computational models and process intensification

- Pharmaceuticals: continuous processes for tailored crystals & nano-particles

- Foods & cosmetics: crystals, emulsions, nano-dispersions, structured liquids

These goals are being pursued by mastering multiphase flows with phase change, by developing multi-scale computational models and by developing novel fluidic device platforms to realize new insights, innovations & intensification solutions. This new knowledge is expected to expand, enrich and strengthen the chemical engineering domain and impact on society

Research Interests

Multi-scale/ multi-layer modelling of multiphase systems

- Computational flow modelling – experiments – flows with phase change

- Ensemble approaches: machine learning + phenomenological models

Development of fluidic devices without moving parts

- Vortex diode, Fluidic oscillators, Impinging jets, Pinched tubes, Falling film devices

Process intensification, chemical reactor engineering, scale-up

-

Multiphase reactors, fluidic devices as reactors

Developing applications & processes

- Droplets (emulsions) and particles (crystals, nano-particles, catalysts)

- Valorisation of biomass: energy, chemicals, materials (fibres)

- Water treatment, recycle and reuse

- Applying computational flow modelling for optimisation – digital twins

Innovation, spin-outs and start-up companies

On-going Research

- Liquid – liquid emulsions with hydrodynamic cavitation (vortex diode and other devices)

- Oxidative desulphurisation (liquid – liquid system)

- Cavitation for biomass pre-treatment/ anaerobic digester

- Cavitation + photo-catalysis

- Multi-scale models for linking performance with device design: water treatment

- Cavi-crystallisation

- Crystallisation in fluidic oscillator

- Continuous process for nanoparticles

- Crystallisation in devices without moving parts/ machine learning

- Enhancing heat transfer in rotating packed beds (boiling solvents – micro-structured surfaces)

- New ideas for process intensification – Centre on Process Intensification – reactor set-ups

- Hydrogenation reactions/ reactors (four phase systems)

Some Recent Publications

A novel hybrid cavitation process for enhancing and altering rate of disinfection by use of natural oils derived from plants

Mane, M.B., Bhandari, V.M., Balapure, K., Ranade, V.V.

(2020) Ultrasonics Sonochemistry, 61,

DOI: 10.1016/j.ultsonch.2019.104820

Performance of biochar as a catalyst for tar steam reforming: Effect of the porous structure

Buentello-Montoya, D., Zhang, X., Li, J., Ranade, V., Marques, S., Geron, M

Applied Energy, 259,

DOI: 10.1016/j.apenergy.2019.114176

Kinetics of cinnamaldehyde hydrogenation in four phase system

Khan, M., Joshi, S., Ranade, V.

(2019) Chemical Engineering Journal, 377

DOI: 10.1016/j.cej.2018.11.210

Modelling of vortex based hydrodynamic cavitation reactors

Sarvothaman, V.P., Simpson, A.T., Ranade, V.V.

(2019) Chemical Engineering Journal, 377

DOI: 10.1016/j.cej.2018.08.025

Pretreatment of Lignocellulosic Biomass Using Vortex-Based Devices for Cavitation: Influence on Biomethane Potential

Nagarajan, S., Ranade, V.V.

(2019) Industrial and Engineering Chemistry Research, 58 (35), pp. 15975-15988. Cited 1 time.

DOI: 10.1021/acs.iecr.9b00859