The group is leading the metal additive manufacturing activity in the University of Limerick, within the School of Engineering, utilising the Concept Laser Mlab cusing R powder bed fusion system awarded by the GE Additive Education programme. The School of Engineering Mlab system is hosted by Croom Medical under a collaborative agreement, allowing its operation within an industrial setting.

Projects

The group works on a variety of projects involving the experimental investigation - characterisation and constitutive modelling of the elastoplastic behaviour of materials and structures.

Cyclic elastoplastic response and low cycle fatigue (LCF) life prediction of:

- Corroded and non-corroded aluminium alloys (i.e. 7050, 7075, 2024-T3)

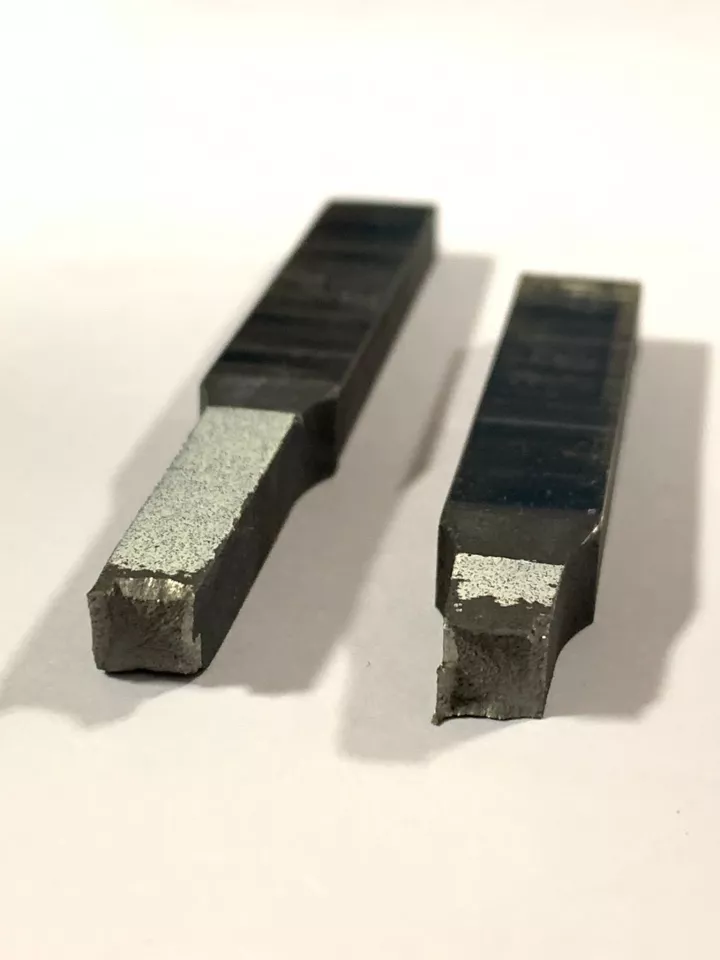

- Powder bed fusion Ti-6Al-4V and maraging steel 300

- Material extrusion steel 316L

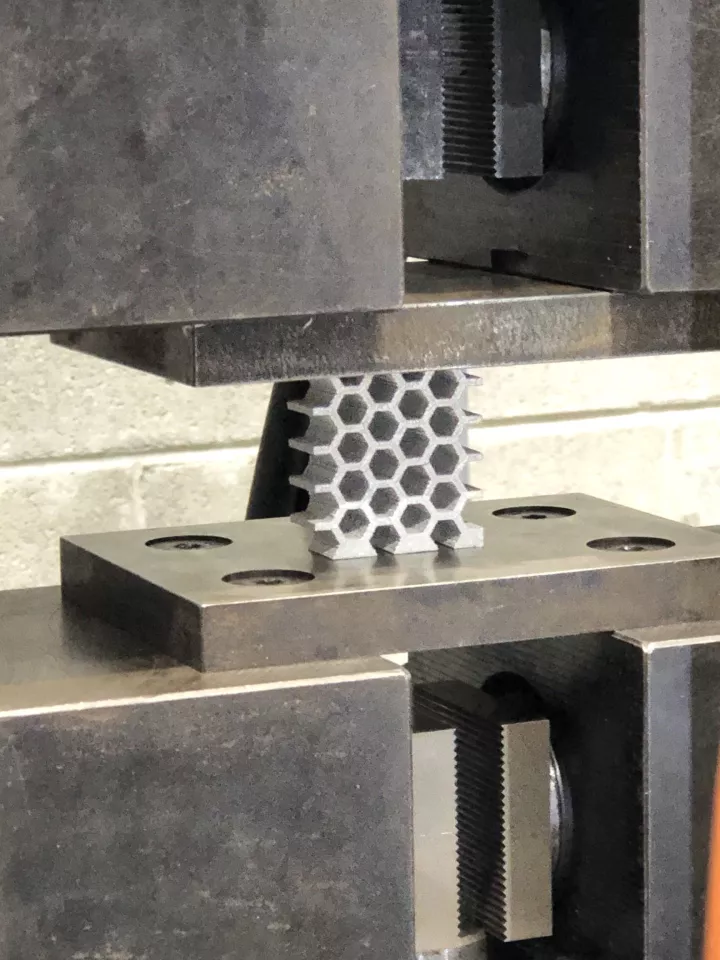

- In-plane compression of powder bed fusion and material extrusion steel 316L honeycombs

- Mechanical performance of powder bed fusion steel 316L bolts towards strength optimisation of aluminium 2024-T3 lap joints

Funding

- PhD scholarship grant for research on 'Physics-informed Mathematical Modelling of Plastic Yielding of Powder Bed Fusion Steel 316L' , University of Limerick, Faculty of Science & Engineering Sustainability Scholarship scheme (2022), D. O'Kiely, K. Kourousis, M. Vynnycky, €95,000.

- Research grant for metallic material fatigue testing and performance evaluation (2022), K. Kourousis, €10,000.

- Award of a GE Concept Laser Mlab cusing R metal additive manufacturing equipment, General Electric, GE Additive Education (2018), K. Kourousis, L. O'Sullivan, D. Tanner, $282,000.

- Grant for postgraduate research scholarship on ‘Plastic Anisotropy of Additively Manufactured Metals’, Irish Research Council (2017), B. Mooney, K. Kourousis, €23,721.

- Seed Grant for research on ‘Metal Additive Manufacturing’, University of Limerick (2016), K. Kourousis, €84,413.

Image

Fabrication of steel 316L honeycomb compression test coupons on the Concept Laser Mlab cusing R

Image

In-plane compression test of material extrusion steel 316L honeycomb

Image

Powder bed fusion maraging steel 300 test specimen